Medical Radiography Systems Rely Heavily on HONSUN's Fiber Optic Components

HONSUN’s fiber optic components have been widely used in medical radiography systems, such as full chest imaging, fluoroscopy, image intensification, dental intraoral x-ray imaging systems, etc. When coupled with CCDs and CMOS sensors, HONSUN’s fiber optic components provide better images.

With optical fiber design, it’s better to reduce radiation exposure to sensors and lower operating costs. The advantages are as follows.

Protect sensor from X-Ray Damages.

Even the best scintillators can’t prevent some X-rays from slipping past the barrier, high-end sensors feature a fiber optic plate to absorb stray X-ray photons. The plate is composed of some Xray absorption material. Which could make the output xray noise as low to 1%.

Some sensor manufacturers exclude fiber optic plates to keep the sensor head thin (and production cost low). However, without the added protection from direct X-rays, it’s hard to guarantee the quality of the final radiography captured with such a sensor.

Reduce Noise and Improve SNR.

Output of the fiber optic plate is a signal made of visible light that can then be sensed by the next layer, the detector. Since the next layer can only produce an image as good as the light it receives, the fiber optic plate plays an important role in protecting the detector from unconverted X-ray photons that cause noise and false data on the final radiograph.

And by adding some absorber inside the fiber optic plate, it could block stray light which will make the image result blur.

Low Browning Configurations.

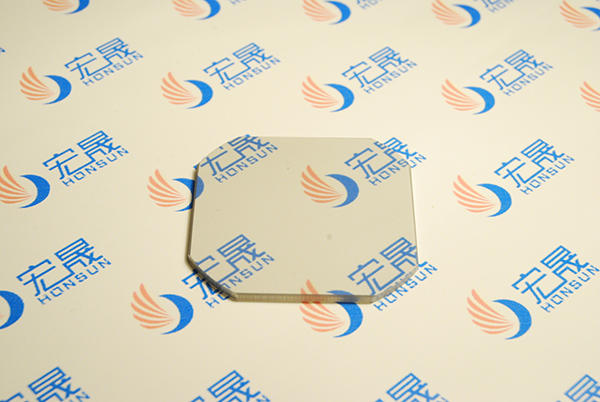

There are several type of fiber optic plate in the market, some of them are optimized specially for Xray proposal. Without certain configuration, fiber optic plate may turn into brown color in long-term use.

Read here for more information about HONSUN's fiber optic plate.

Read here for more information about HONSUN's fiber optic taper.