Application of fiber optic plate in the fingerprint sensors

Is a new miniature optical fingerprint sensor of low cost and high resolution your ultimate goal?

Are you still worried about the plate material of high resolution?

Guangzhou Honsun Opto-electronic Co.,Ltd will completely solve the problem for you!

Introduction

In October 2014, HIS, a marketing research company, predicted that the global market of fingerprint sensor will increase almost four times to nearly $1.7 billion by 2020. Most of the growth will come from Asia, especially China. In 2013, the size of global market for fingerprint sensor used for mobile phones and tablets was only $500 million. We have reasons to believe that so many competitors are rubbing their hands and getting ready to move into this growing market. In fingerprint sensor, how to make choice between optical sensor and capacitance sensor? How can it be miniature, low-cost and with high resolution? The use of fiber optical plate will solve this problem for you!

The Application and Technical Advantages of Fiber Optic Plate in Fingerprint Identification Technology

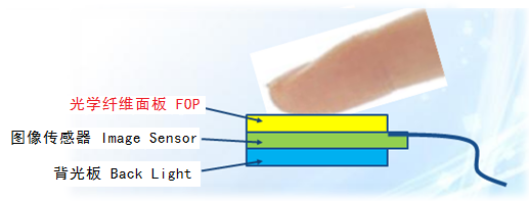

The principle&structure of using fiber optic plate to gather the fingerprint module

As gathering window component,the fiber optic plate can transmit fingerprint image with 1:1 high definition and high fidelity. The image transmission effect is just like a finger directly pressing on the image sensor directly.

Contrast with the common technologies of fingerprint acquisition.

|

Performance comparison |

||||

|

Items |

Traditional Optical Technology |

Silicon Chip Technology (capacitive)

|

Ultrasonic Technology (Radio frequency type) |

Fiber Optic Plate Technology |

|

Volume |

medium |

small |

big |

small |

|

Structure |

simple |

complex |

complex |

simple |

|

Resolution |

>500dpi |

>500dpi |

>700dpi |

>500dpi |

|

Durability |

durable |

damageable |

medium |

durable |

|

Power consumption |

less |

medium |

more |

less |

|

Cost |

low |

medium |

high |

low |

|

Imaging capability |

medium (The imaging of dry finger is poor and sweaty and dirty finger make image vague ) |

stronger ( Sweaty and dirty finger cannot image, and it needs to get image from real skin.) |

strongest |

strongest (It needs to keep finger dry and clean.) |

|

Safety |

low |

medium |

highest |

higher |

The Structural Principle of Fiber Optic Plate

Fiber Optic Plate

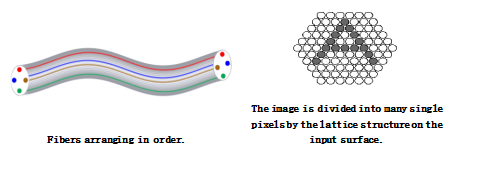

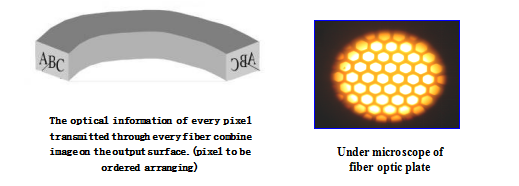

Fiber Optic Plate (hereinafter referred to FOP) is a glass product composed of many optical fibers by parallel arranging, screen pressing and cold working. It can transmit the optical image from one side to the other with high resolution in zero optical path (zero thickness) , as shown in the pictures.

The resolution of general fiber optic plate can be 4200 ppi. Products with the resolution ≤6000ppi can be customized according to customer's requirements. The dimension can also be customized according to customer's request.

The structural principle diagrams of fiber optic plate:

The Introduction of Guangzhou Honsun Opto-electronic Co.,Ltd.

Guangzhou Honsun Opto-electronic Co.,Ltd is the first enterprise manufacturing fiber optical plates in China. It has rich experience for more than 40 years in the production and research&development of fiber optic plates. With advanced manufacturing technology, mature technique, and high production efficiency, Honsun is also the unique enterprise that can produce civil fiber optic plates in a large-scale.

Honsun has became the enterprise with largest manufacturing capacity of fiber optic plates. It has the world’s largest production line of fiber drawing production. More than 60 sets of fiber drawing towers has been put into operation, and nearly 30 sets is under construction. The total number is nearly 150 sets.

With strong research ability, high product quality and good after-sales service, Honsun has won high praises from all parties, and has establish a mutual win-win cooperation situation with customers and suppliers. As the enterprise scale grows rapidly, Honsun is now developing new civil fields and hopes to cooperate with all parties to create the prosperous future hand in hand.

Honsun’s capacity of fiber optic plate in fingerprint identification is 10 million per month.